Automation Engineering Program Highlights

Gain the skills to design and implement high-precision machinery with an automation engineer degree.

As modern manufacturing evolves, there is a growing demand for machines that can produce increasingly complex components with speed, accuracy, and cost efficiency. Automation engineers bridge the gap between traditional engineering design and cutting-edge technologies, such as industrial robotics, programmable automation controllers, and data visualization tools. They are essential in developing and maintaining advanced manufacturing systems that align with the principles of Industry 4.0.

As a student in the automation engineering program, you will:

- Learn foundational and advanced engineering design principles tailored to automated systems.

- Gain hands-on experience with industrial robotics and process control techniques to develop real-world automation solutions.

- Build strong problem-solving skills through practical exercises in troubleshooting and maintenance.

- Strengthen soft skills with an emphasis on professional communication, including solution-focused presentations, quality control reporting, and maintenance planning.

Additional automation degree highlights include:

- Accelerated completion: The automation engineer degree can be completed in as little as 3 years, including summer terms.

- Flexible learning options: The final four semesters of the automation engineering degree may be completed online, allowing greater flexibility for working professionals or students outside the area.

- Transfer-friendly pathway: Students who have already completed a mechatronics degree, or a degree in a closely related field, may be able to transfer into the automation degree and complete their bachelor’s degree in a shorter timeframe. They can also finish the remaining coursework online.

Learn Your Way

Automation engineering courses are available on our Cadillac campus. Part of this program is completed online.

Learn MoreWhy Become an Automation Engineer?

The manufacture and assembly of precision components and products depend on mechanical systems controlled by electronic equipment. These systems are designed, constructed, built, programmed, tested, and installed by engineers who are cross-trained in multiple disciplines, and they apply their broad-based knowledge and technical skills to ensure that equipment and systems function smoothly and efficiently.

Curriculum

The Baker College automation engineering technology degree is a 4-year program consisting of 120 credit hours (90 hours of automation engineering courses and 30 hours of general education credits). Our curriculum includes courses in computer aided design, electrical technology and circuits, industrial controls and instrumentation, mechanical design, and a capstone project.

Sample Courses

Integrated Systems

Programmable Logic Controller Application

Capstone Project I

Frequently Asked Questions

Automation engineering is the field focused on designing, developing, and managing systems that control machinery and processes with minimal human intervention. It combines principles from mechanical, electrical, and software engineering to create efficient, precise, and reliable automated systems.

At Baker, students learn to work with robotics, programmable logic controllers (PLCs), and advanced control systems, preparing them to improve manufacturing and production processes. This multidisciplinary approach helps graduates solve complex real-world problems and meet the growing demand for automation in various industries. Learn more about automation engineering.

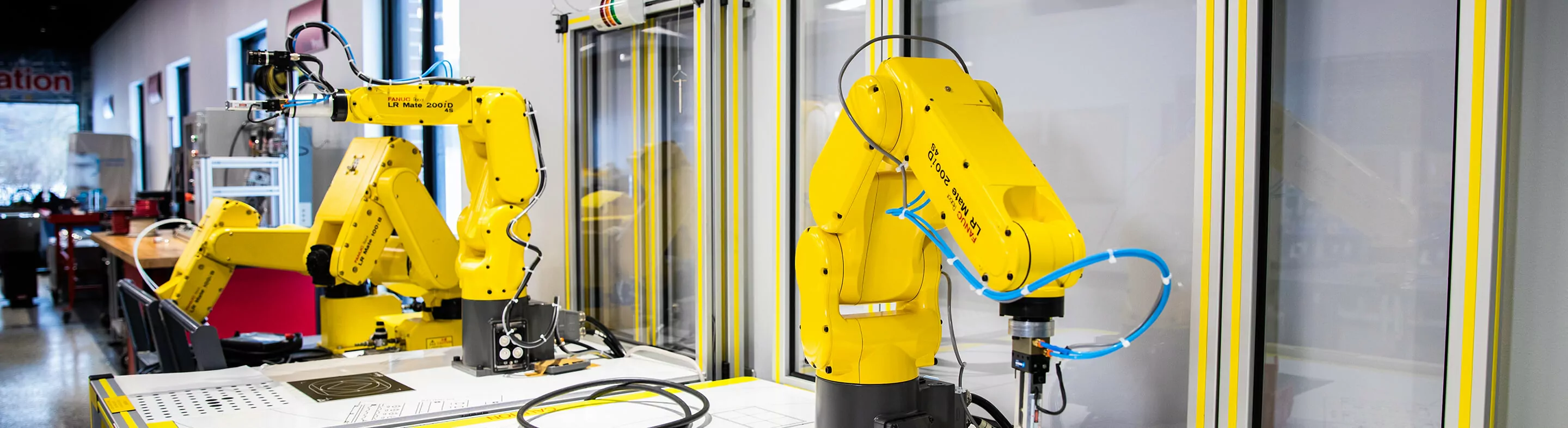

Baker’s automation engineer degree stands out for its deep commitment to hands-on, real-world learning, integrating traditional engineering design methods with industrial robotics, PLCs, and process-control techniques directly in lab settings.

Students gain practical skills through extensive troubleshooting exercises and real-world problem solving—perfectly mirroring the demands of modern manufacturing and Industry 4.0 environments. Included is a capstone experience where students design, build, and qualify their own automated system projects, demonstrating their proficiency and career readiness.Yes! The automation engineering courses are designed to emphasize real-world problem-solving and troubleshooting, preparing students to design, build, and maintain automated manufacturing systems from day one.

Students start with early hands-on experience in foundational lab courses, working with basic control devices and instrumentation. As they progress, they build on these skills through more advanced work with PLC programming, industrial sensors, and complex troubleshooting exercises. In the advanced stages, students gain experience integrating robotics, sophisticated systems, and comprehensive process-control projects.Finally, the automation engineering technology program culminates in a capstone project where students design, implement, and test a full-scale automation solution, showcasing their practical skills to future employers.

Together, these lab and project experiences ensure students develop steadily from foundational to advanced proficiency—graduating fully career-ready with robust, real-world experience in industrial automation.

In the automation engineer degree, you’ll take a mix of technical, hands-on, and theory-based courses designed to prepare you for modern, high-tech automation careers. Core topics include programmable logic controllers (PLCs), industrial robotics, control systems, computer-aided design (CAD), automation integration, hydraulics, pneumatics, and electronics. You’ll also build essential engineering foundations through courses in math, physics, and technical writing.

Alongside classroom learning, you’ll complete progressive lab courses that give you practical, hands-on experience, and finish with a comprehensive capstone project. Together, these courses ensure you graduate with both the technical knowledge and the real-world skills needed to succeed in the automation field.The Bachelor of Science in Automation Engineering Technology is a 120-credit program designed to be completed in an average of three years of full-time study.

This timeline includes a blend of general education, core automation engineering coursework, progressive hands-on lab experiences, and capstone projects. The structured sequence and on-campus delivery ensure students move efficiently toward graduation and workforce readiness.

At the Cadillac campus, automation engineering students have access to professionally outfitted hands-on labs and classrooms equipped with industry-standard tools used in real-world environments.

You’ll work directly with industrial robotics, programmable logic controllers, and process-control systems, gaining practical experience that mirrors what you'll encounter in the workforce.The Cadillac campus features:

- Modern lab spaces equipped with the latest automation and engineering tools

- Dedicated classrooms for lectures and collaborative projects

- Broad academic resources such as the Academic Resource Center, tutoring support, and computer labs to reinforce your hands-on learning

These facilities ensure you receive a robust, career-ready education through immersive and applied technical training.

An automation engineer designs, develops, and manages automated systems to streamline industrial processes and enhance efficiency using cutting-edge technologies like robotics and PLCs. They work with stakeholders to define automation goals, create system designs with precise hardware and software integration, and write code to bring these systems to life.

Beyond design, automation engineers install, test, and troubleshoot equipment, ensuring everything runs safely, reliably, and in compliance with industry regulations. They also perform ongoing maintenance and optimization to enhance system performance and productivity over time. Read more about what an automation engineer does.In the automation engineer program, you’ll develop a powerful combination of technical and professional skills to prepare you for modern engineering and manufacturing roles. You’ll gain hands-on expertise in programmable logic controllers (PLCs), industrial robotics, electrical and mechanical systems, hydraulics, pneumatics, and control systems design.

You’ll also build strong problem-solving and troubleshooting abilities, learn to design and integrate automated systems, and develop technical communication and project management skills. By working through progressive lab experiences and a comprehensive capstone project, you’ll graduate with the confidence and practical knowledge needed to thrive in high-demand automation careers.Students in Baker’s automation engineering program are prepared to pursue industry-recognized certifications that enhance their career opportunities. Options include the Certified Automation Professional (CAP) and Certified Control Systems Technician (CCST) from the International Society of Automation, as well as manufacturer-specific certifications from companies like Rockwell Automation and Siemens. These credentials help validate your technical skills and demonstrate your readiness for advanced roles in the field. Learn more about available certification options.

Graduates can pursue a wide range of automation careers in advanced manufacturing and technology fields. Common roles include automation engineer, controls engineer, robotics technician, systems integrator, and PLC programmer.

You could also work as a maintenance and automation specialist, process engineer, or manufacturing systems designer. These positions are in high demand across industries like automotive, aerospace, food and beverage, medical device manufacturing, and more—giving you flexible, rewarding career options after graduation.

From Mechatronics to Automation: A Seamless Pathway

The AAS in Mechatronics provides a solid foundation in mechanical systems, electronics, sensors, and basic automation, preparing students to work with and maintain electromechanical systems.

The automation engineering degree takes that foundation further by focusing on:

- Advanced control systems, including PLCs, PACs, and SCADA

- Industrial robotics integration and programming for automation

- Smart manufacturing and Industry 4.0 technologies, including IoT devices, real-time data collection, and quality control methods

- System-level thinking enables students to design, implement, and optimize complex automated processes across various industries

- Transfer options that recognize prior learning and allow qualified students to enter the program at an advanced level, often reducing time to graduation

- Flexible delivery, with upper-level coursework available online to accommodate different learning needs and schedules

Together, these programs create a clear academic and career pathway—from technician-level roles in mechatronics to engineering-level positions in automation design, integration, and leadership.

On Campus Available

View campus locationsUnavailable on Baker Online

Core courses for this degree program are not offered through Baker Online.

For those interested, a selection of general education and prerequisite courses are available through Baker Online each semester.

Baker OnlineUnavailable on Online Live

Core courses for this degree program are not offered through Online Live.

For those interested, a selection of general education and prerequisite courses are available through Online Live each semester.

Online Live